The Best Commercial Refrigeration Repair Companies in Toronto Revealed

Wiki Article

Troubleshooting Commercial Refrigeration Repair: Approaches for Quick and Effective Fixes

In the world of industrial refrigeration, the demand for swift and exact troubleshooting techniques is paramount. When a refrigeration system malfunctions, the effects can be costly and disruptive to organization procedures. Comprehending the usual issues that torment industrial refrigeration systems and having a toolkit of diagnostic methods at your disposal can make all the difference in swiftly recognizing and fixing problems. As we navigate through the intricacies of fixing industrial refrigeration fixing, we will certainly discover the key techniques for resolving problems successfully, making sure that services can maintain ideal air conditioning performance and reduce downtime.Typical Commercial Refrigeration Concerns

Business refrigeration systems frequently experience a range of functional problems that can disrupt their performance and efficiency. One prevalent concern is incorrect temperature level control, which can lead to food perishing and waste if not without delay attended to.Furthermore, cooling agent leakages pose a substantial concern as they not only influence the cooling ability of the system but also add to ecological damage. Detecting and fixing leaks without delay is important to protect against more damage and make sure conformity with policies. In addition, filthy condenser coils can restrain heat transfer, requiring the system to function more difficult and eat more energy. Regular cleansing and upkeep can help avoid this problem and lengthen the life expectancy of the refrigeration system.

Diagnostic Devices and Strategies

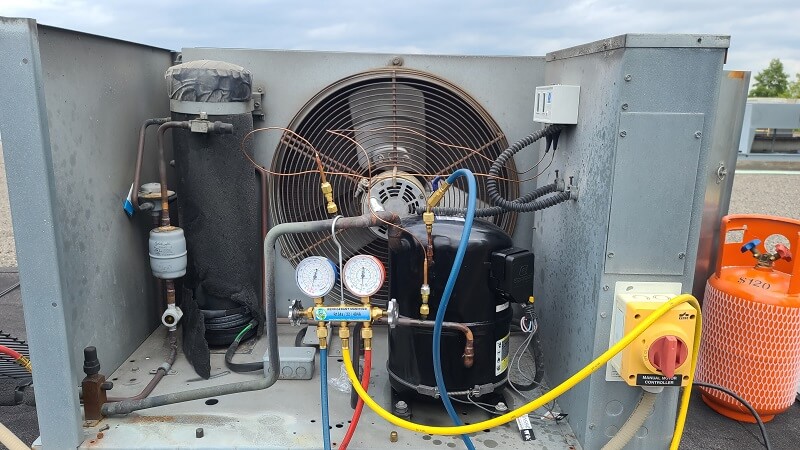

Effective troubleshooting of industrial refrigeration systems depends greatly on making use of specialized analysis devices and techniques to identify and resolve underlying concerns successfully. One essential diagnostic tool is the multimeter, which aids technicians measure voltage, current, and resistance in various elements such as compressors, motors, and defrost heating units. Thermometers are likewise vital for analyzing temperature differentials across the system to pinpoint potential problems like refrigerant leakages or improper air flow. In addition, leakage detection tools like electronic leakage detectors or ultraviolet color sets are crucial for situating refrigerant leakages that can cause system inadequacies.Methods such as pressure screening utilizing manifold evaluates can figure out if the system has the correct cooling agent fee and identify any type of leakages. Aesthetic assessments of components for indications of ice, deterioration, or wear build-up are additionally fundamental in detecting issues. Moreover, data loggers can be utilized to monitor system performance with time and spot patterns that might indicate repeating issues. By incorporating these diagnostic devices and strategies, service technicians can effectively repair commercial refrigeration systems and offer fast and precise repairs, reducing downtime and making certain optimal system performance.

Quick Fixes for Refrigeration Problems

When faced with refrigeration issues, service technicians can carry out quick repairs to attend to usual issues swiftly and effectively. If the refrigeration system is not cooling down correctly, inspecting and changing the thermostat setups might offer a fast solution before more extensive troubleshooting is required. By carrying out these quick solutions, service technicians can address usual refrigeration issues successfully and keep business refrigeration systems running efficiently.

Preventative Maintenance Tips

Implementing a positive maintenance routine is crucial for making certain the durability and optimum efficiency of industrial refrigeration systems. Regular maintenance not just helps prevent costly failures yet also makes sure that the equipment runs effectively, conserving energy and lowering total operating expense. Right here are some preventative upkeep tips to maintain business refrigeration systems running smoothly:

Check and Replace Filters: Filthy filters can limit airflow, making the system job more difficult and possibly triggering damage. Examine and replace filters regularly to avoid issues.

Inspect Seals and Gaskets: Leaky seals and gaskets can bring about temperature changes and power wastage. Changing and inspecting harmed seals can aid preserve regular temperatures.

Professional Support and Solutions

To maintain the optimum efficiency accomplished with normal preventative maintenance, seeking professional assistance and services for business refrigeration systems is necessary. Professional technicians have the experience and specialized understanding needed to identify and resolve complicated issues effectively. When facing difficult refrigeration troubles, relying upon expert assistance can save both time and money in the future.Professional services use benefits such as access to sophisticated tools and devices, making certain that repair work are accomplished efficiently. Furthermore, professionals are trained to abide by sector guidelines and safety requirements, lowering the risk of accidents and making certain conformity with legal requirements.

Verdict

Finally, repairing commercial refrigeration fixing needs an organized strategy to identifying typical concerns, using diagnostic tools and methods, applying quick repairs, and prioritizing preventative maintenance. Expert assistance and solutions might be required for even more facility troubles - Toronto commercial refrigerator repair. By following these strategies, services can guarantee their refrigeration systems run successfully and effectively, minimizing downtime and prospective lossesRecognizing the usual concerns that plague commercial refrigeration systems and having a toolkit of diagnostic techniques at your disposal can make all the difference in quickly determining and correcting issues.Reliable troubleshooting of business refrigeration systems counts greatly on making use of specialized analysis tools and strategies to recognize and deal with underlying issues efficiently. By incorporating these diagnostic devices and strategies, technicians can effectively troubleshoot business refrigeration systems and provide quick and precise repair work, reducing downtime and ensuring optimal system performance.

By executing these quick fixes, service technicians can address common refrigeration troubles successfully and maintain business refrigeration systems running efficiently.

In addition, expert support can help expand the life expectancy of commercial refrigeration systems by recognizing prospective issues prior to they escalate.

Report this wiki page